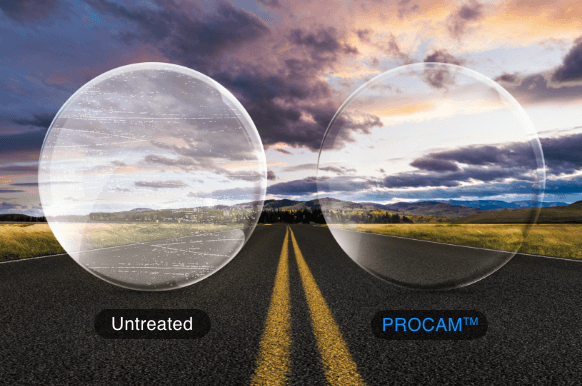

PROCAMTM

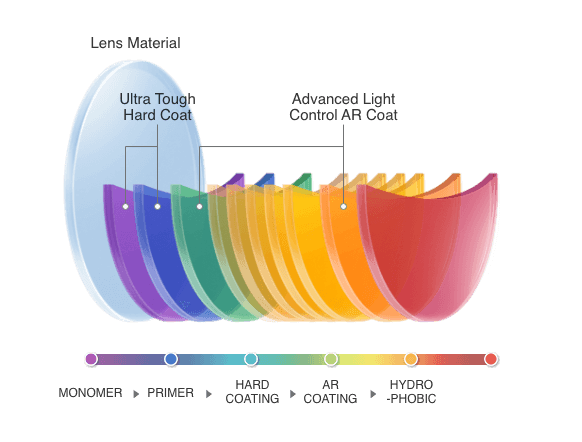

Surface coating solution We have various functional coating products using nano-particle sol.-

High Performance

High Performance

Coating Solution -

High Functional

High Functional

Monomer -

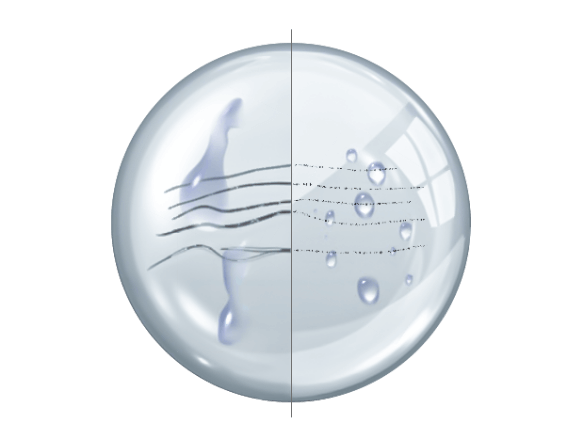

Syper Hydrophobic

Syper Hydrophobic

Solution

They are designed to enhance abrasive resistance scratch & hardness and own surface property for optical lens, sunglasses, and other substrates.

Optical monomers

Our main items are coating materials and optical monomers for spectacle lenses.

They can apply to various refractive index as well as tinting/non-tinting lens.

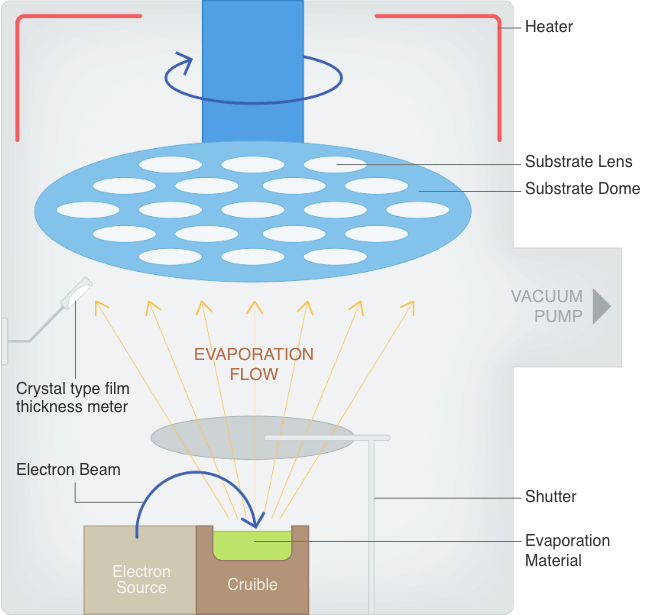

Vacuum Evaporation

Coating System

vaccum chamber

Evaporation (Deposition)

Evaporation is a common method of thin-film deposition. The source material is evaporated in a vacuum. The vacuum allows vapor particles to travel directly to the target object (substrate),

where they condense back to a solid-state.

Evaporation is used in microfabrication, and in making macro-scale products such as metalized plastic film.

Equipment

In the thermal method, a metal material (in the form of wire, pellets, shot) is fed onto heated semimetal (ceramic) evaporators known as “boats” due to their shape. A pool of melted metal forms in the boat cavity and evaporates into a cloud above the source.

Alternatively, the source material is placed in a crucible, which is radiatively heated by an electric filament, or the source material may be hung from the filament itself (filament evaporation).

Evaporation coating layer

Classification of High Vacuum Coating Materials